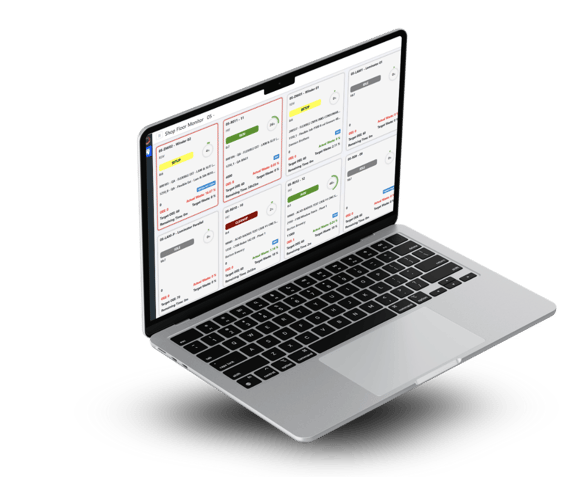

Shop Floor Data Management

Know All Your Production Details in Real-Time With Shop Floor Management Software

Unlock Real-Time Production Intelligence with AC4D - Cut Costs, Reduce Downtime, and Maximize Performance Across Every Machine.

Benefits

AC4D integrates seamlessly with your existing workflows - from industry-specific ERP systems like Radius® and CBS (for corrugated), to generic platforms like SAP, as well as MES systems and advanced scheduling tools such as PrintFlow® 4D (PF4D), CorrPlan, and Digital Front End systems.

By monitoring run-order and machine status information, AC4D gives plant managers complete visibility and traceability across the entire production process—enabling smarter decisions, faster responses, and streamlined operations.

Real-Time Monitoring

Get accurate and up-to-date run-order and machine status information, allowing you to make informed decisions and plan production proactively.

Enhance Quality Control

Tailored quality questionnaires and product tests, simplify the process of tracking item-specific data. Comprehensive inventory tracking and traceability allow for consistent high-quality output.

Data-Driven Reports

Advanced reporting capabilities enable complete enterprise and single-plant visibility, making spotting problem areas and improving processes easy.

Compliance and Traceability

AC4D supports manufacturing traceability and quality questions for compliance, ensuring your business meets regulatory requirements and can quickly trace products in the event of an issue.

Improve Processes and Production Quality

With data-driven reports and complete plant visibility, managers can quickly identify problem areas and refine processes to improve production efficiency and final product quality.

Real-Time Monitoring

Get accurate and up-to-date run-order and machine status information, allowing you to make informed decisions and plan production proactively.

Enhance Quality Control

Tailored quality questionnaires and product tests, simplify the process of tracking item-specific data. Comprehensive inventory tracking and traceability allow for consistent high-quality output.

Data-Driven Reports

Advanced reporting capabilities enable complete enterprise and single-plant visibility, making spotting problem areas and improving processes easy.

Compliance and Traceability

AC4D supports manufacturing traceability and quality questions for compliance, ensuring your business meets regulatory requirements and can quickly trace products in the event of an issue.

Improve Processes and Production Quality

With data-driven reports and complete plant visibility, managers can quickly identify problem areas and refine processes to improve production efficiency and final product quality.

Waste Reduction

The Direct Machine Interface (DMI) prevents under and overrunning jobs, reducing waste (typically by 2%) and employee time needed to guarantee order fulfillment.

Streamline Production and Improve Efficiency by up to 20%

Leverage the power of cutting-edge technology to optimize your production processes and boost efficiency by up to an impressive 20%.

AC4D is built on an intuitive browser-based interface, providing easy access to critical information from any location. Benefiting from integration with leading ERP applications, AC4D ensures a seamless flow of data and streamlined operations across your entire enterprise.

Streamlining Production and Optimizing Efficiency With Minimal Touch Points

Businesses can achieve faster and more seamless production workflows by reducing unnecessary interactions and implementing remote deployment strategies.

This approach boosts productivity, enables cost savings, and improves overall operational effectiveness.

Find out How Shop Floor Data Management Can Benefit Your Business

We are eager to learn how we can help you. To start a conversation centered on your goals, simply complete this short form.

Frequently Asked Questions

How does Auto-Count 4D streamline shop floor data collection?

Auto-Count 4D automates the collection of real-time production data from machines, providing insights into performance, downtime, and material usage.

This allows manufacturers to identify inefficiencies quickly and make data-driven decisions to improve production.

How does AC4D improve production efficiency?

By providing real-time data on machine performance and material usage, AC4D helps manufacturers optimize their operations, reduce waste, and minimize downtime. This leads to more efficient production processes and higher output.

Can AC4D track specific metrics like setup time and downtime?

Yes, AC4D tracks critical production metrics, including setup time, downtime, and output rates. This data enables manufacturers to monitor and improve equipment efficiency and overall production performance.

How does Auto-Count 4D integrate with other ePS solutions?

Auto-Count 4D integrates seamlessly with RadiusERP and PrintFlow 4D, providing a comprehensive solution for managing production data.

This integration ensures that real-time shop floor data is reflected in scheduling, estimating, and ERP processes.

How does AC4D help manufacturers improve Overall Equipment Effectiveness (OEE)?

AC4D tracks key OEE metrics, including machine availability, performance, and quality. By analyzing these metrics in real-time, manufacturers can identify areas for improvement and implement strategies to boost overall equipment effectiveness.